Professional Benefits: Designing Flexibility

Whether you are an architect or an engineering consultant for residential,

commercial or industrial developments - specifying the Hi-Tech System for your

client offers the ultimate in affordable quality paired with design flexibility.

Our customized, modular building technology can accommodate hi-rise, low-rise and

single-family designs without restricting your creativity - and the final product

can cost up to 30% less than conventional construction.

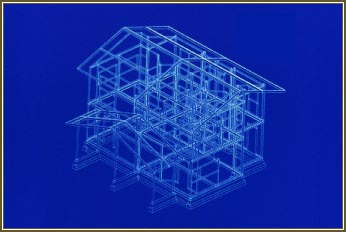

Computer-Engineered Design & Construction - How it Works:

CAD

First, a detailed architectural plan is scanned into a computer by a Hi-Tech

design engineer. Using Hi-Tech�s patented technology system the computer runs

over 70 iterations of the design and produces a structural 3-D model of the building

configured with Hi-Tech panels. Panel shapes and sizes are optimized for code, stress

and aesthetic requirements and take into consideration site, transportation and budget

constraints. Architectural drawings and material specifications are produced by the

computer for review with the client.

CAM

The computer directs robotic arms and laser cutters to shape, cut and fit steel

frames and rigid foam insulation cores exact to the design specifications. Steel

reinforcing cables within the panel are connected to the steel frame and tensioned

to provide diagonal stiffness. Concrete is then applied and bonds to the panel

elements, finishing the interior and exterior of the completed panel.

There are no molds. The steel frame and pre-formed rigid insulation core form an

individual panel mold, eliminating all design constraints - and the high manufacturing

costs associated with disposable molds.

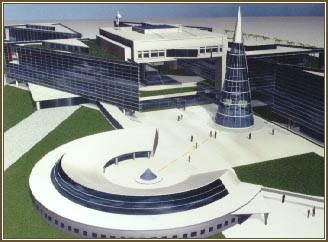

Architectural Flexibility:

While most prefab structures are restricted to a limited set of physical layouts and aesthetic

features, Hi-Tech�s System offers maximum flexibility for design innovation and style

preferences. Vaulted ceilings, cantilevered structures and cutouts are all demonstrated

in our showhome. In fact Hi-Tech panels can be configured to achieve any geometric

shape an architect can imagine. And it�s flexible enough to allow for future

architectural alterations and additions.

The Finishing Touch:

Both internal and external panel surfaces are factory-finished and pre-serviced with

electrical, plumbing and mechanical systems. Hi-Tech facilitates compliance with local

codes to secure necessary permits and approvals.

A wide range of exterior finishes can be used on the panels, including, aluminum or wood

siding and acrylic stucco. Interiors can be painted, covered with paper, fabric or leather,

clad with stone, wood or other materials.

The Strength of a Superior Product:

Extensive tests have been conducted on the Hi-Tech System panels. Test results confirm that

the panels can resist all natural forces, such as earthquakes and hurricane-force

(300mph) winds, by filtering the induced stress outside the connection system.

The walls, floors and roof are fitted together with unique steel joints that allow

for quick assembly and add strength unmatched by any wood-frame design. And Hi-Tech

panels are impervious to bacteria, rodents, termites and other insects.

So now you can spec a product that will deliver maximum benefits to your clients and let

you unleash your creative spirit. Hear what some of the top architects have to say

about the Hi-Tech System:

|

Dr. Omar Take

|

Kenzo Tange Associates, Paris

Vice President

|

"...Professor Kenzo Tange believes that the revolutionary system that you have created is indeed a breakthrough in the construction industry, particularly because it does not compromise the design quality and flexibility. The IHI system differs from any other existing pre-fabricated system because it offers limitless possibilities to architects to freely create any architectural design that answers the needs, budget and requirements of their clients."

|

Gerald Hamilton

|

Gerald Hamilton Architects, Vancouver

M.A.I.B.C., Dip.Arch., F.R.I.B.A., M.R.A.I.V.C., M.S.A.,

Mex. (Hon.), K.St.J.

Past Director & Chairman, IHI

|

"All my life I have looked for a system that is not hampered by the restrictions of molds and with the advent of sophisticated computer programs it is now possible, on an assembly line basis, to create any shapes. When you consider that there have been next to no advancements in the construction industry in the last 70 years, this means a great deal to a world that has been sorely looking for affordable housing both in the industrial and developing world.

Our aim is to provide flexibility without monotony and to achieve our economies for our single to multi-storey buildings of different types by exactness of manufacture and speed of erection."

Come on in and walk through our On-Line Home Show of our Hi-Tech house in Luxembourg,

Or put on your hardhat, become a crane operator and put together the Show Home as you Build Your Own Project

And don�t forget to contact us so that we can take the next step towards doing business together.

Join the Hi-Tech Revolution!